At ARaymond, we draw from over 30 years of experience designing and producing cleaning system sub-components in-house.

We work closely with our customers to come up with value-creating cleaning solutions, from speeding up the assembly time and guaranteeing efficient fluid usage to ensure impeccable cleaning of front and rear windshields, lamps, LIDAR, ADAS sensors, and camera lenses.

Windshield washer nozzles for optimized cleaning performance

Lightweight and removable, the windshield nozzles are designed to be integrated with sealing in tight packaging space. They can be heated and equipped with an oscillating spray pattern to ensure maximum cleaning performance at any vehicle speed.

Expanded windshield cleaning for ADAS front camera

Many advanced driver assistance systems have front cameras placed in the upper part of the windshield. For the camera to deliver a reliable image, the shield must be kept clean. Washer arms are excellent at ensuring the camera remains unobstructed. Water is sprayed precisely for optimal cleaning and water consumption even at high speeds, and standard wiper blades can be used.

ARaymond creates innovative ADAS camera cleaning solutions that integrate directly into the washer arm and undergo extensive testing and fine-tuning for optimal cleaning. The assembly process is fully automated and undergoes quality controls at every step, including HD camera inspection to check the spray pattern. To learn more, watch the video.

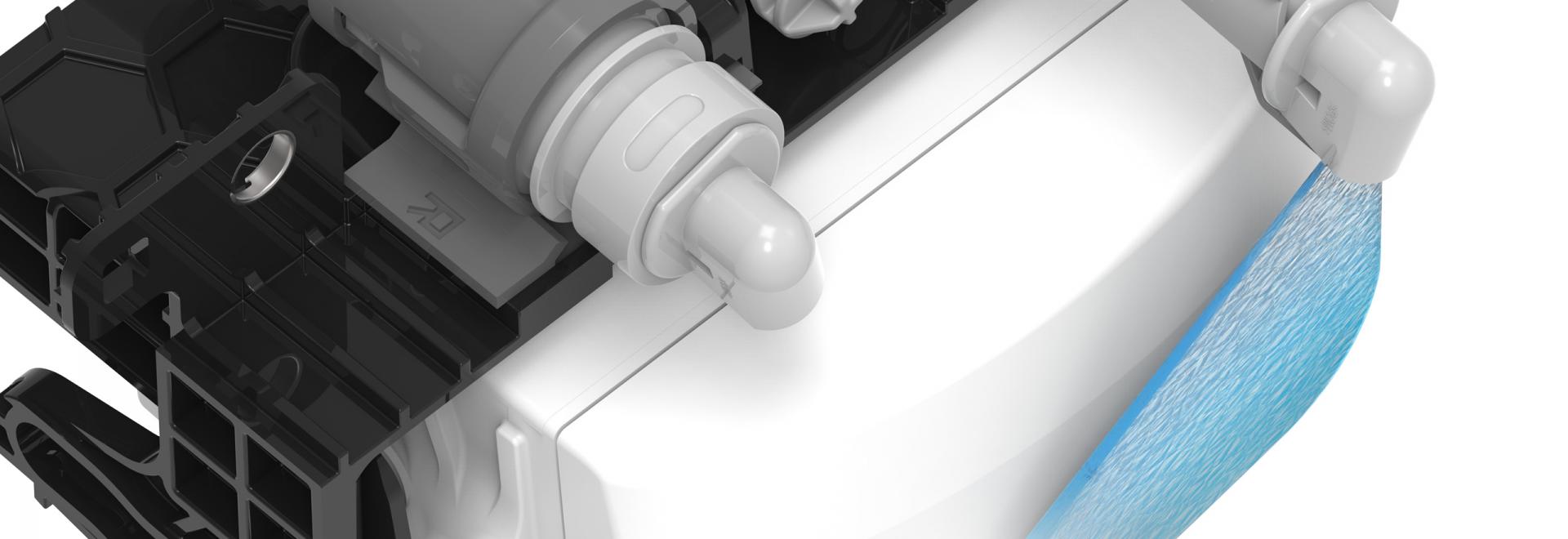

Rear washer nozzles

Compact and powerful cleaning nozzles for rear windshields that can be equipped with non-return valves and different fluidic chips depending on the required fan spray angle.

High-precision ADAS camera and sensor cleaning

As demand for ADAS and autonomous driving systems grows, the number of on-board cameras and sensors in vehicles will continue to increase. Vehicles are already overcrowded with subsystems, and space-saving innovations are more important than ever. ARaymond designs and manufactures compact, flexible, easy-to-integrate camera and sensor cleaning solutions that can fit into even the most complex architectures.

- Ultra-low-profile nozzles for a precision jet

- Optional space savers like integrated non-return valves

- Standard components with design flexibility for good carryover and cost efficiency.

All-in-one cleaning for autonomous vehicle cameras

A liquid sprayer and air-jet dryer are combined in a dual-nozzle cleaning solution. The water spray cleans dirt and grime, and the air jet removes any remaining water droplets. Multiple outlets ensure complete coverage of round autonomous vehicle camera lenses.

LiDAR cleaning, integration, and protection

We develop and manufacture complete LiDAR integration, protection, and cleaning solutions, drawing on many ARaymond innovations to increase system performance.

- Telescopic cleaning nozzles are invisible when not in use.

- A robust adjustable bracket holds both the LiDAR and cleaning nozzles in place.

- A mechanical fuse protection system causes the LiDAR to automatically retract in the event of a low-speed impact to prevent damage.

- Electromagnetic valves shorten the cleaning reaction time.

- Tubes and routing management components are carefully selected.

- Tube holders ensure solid, long-lasting fastening.

Factory-tested cleaning performance

ADAS camera and sensor cleaning requirements are constantly evolving. ARaymond’s in-house testing lab ensures that our customers always get optimal cleaning performance.

- Dirt and grime are applied to ADAS sensors to test cleaning efficiency of different pressure levels, spray times, positionings, and air/water spray combinations.

- Cleaning efficiency is measured with high-speed cameras.

- The results are used to constantly improve product specifications.

Our lab also works with customers, providing them with value-added information on complete system requirements and collaborating on new system standards.

Electromagnetic valves for improved sensor cleaning

Autonomous driving vehicles require high performing-cleaning to avoid system failure. Electromagnetic valves, or e-valves, can drastically improve camera and sensor cleaning system performance. At ARaymond, our engineers have developed e-valves with a short reaction time suitable for high pressure cleaning with water and air.

Electromagnetic on/off valve

These valves provide high-speed cleaning, and lowering water consumption, and are compatible with both water and air. The e-valves can be positioned either in an array close to the nozzle or manifold in a centralized location in the vehicle in order to distribute the fluid in the most efficient way on multiple cleaning nozzles. Inlets, outlets and the electrical connector can be sized to the desired system requirements, optimizing the integration in terms of space and weight.