As the automotive industry continues to evolve, the acceptance of Electric and Hybrid vehicles becomes mainstream. Changes are trickling down to all aspects of these vehicles, including the fasteners and assembly systems used.

While the industry navigates this transition, at ARaymond we’re working hand in hand with our mobility customers to develop thermal management products that improve the ergonomics, safety, and efficiency of the assembly process and of the vehicle’s performance.

Safety improvements

Effective thermal management is crucial in the construction of an electric vehicle (EV) with dozens of connection points during the assembly process . An EV system, including its battery pack, must be properly cooled so it operates safely. It is essential to secure all fluid lines to avoid any leakage inside a battery pack or close to electric components, and OEMs are increasing demands regarding safe connections and product traceability.

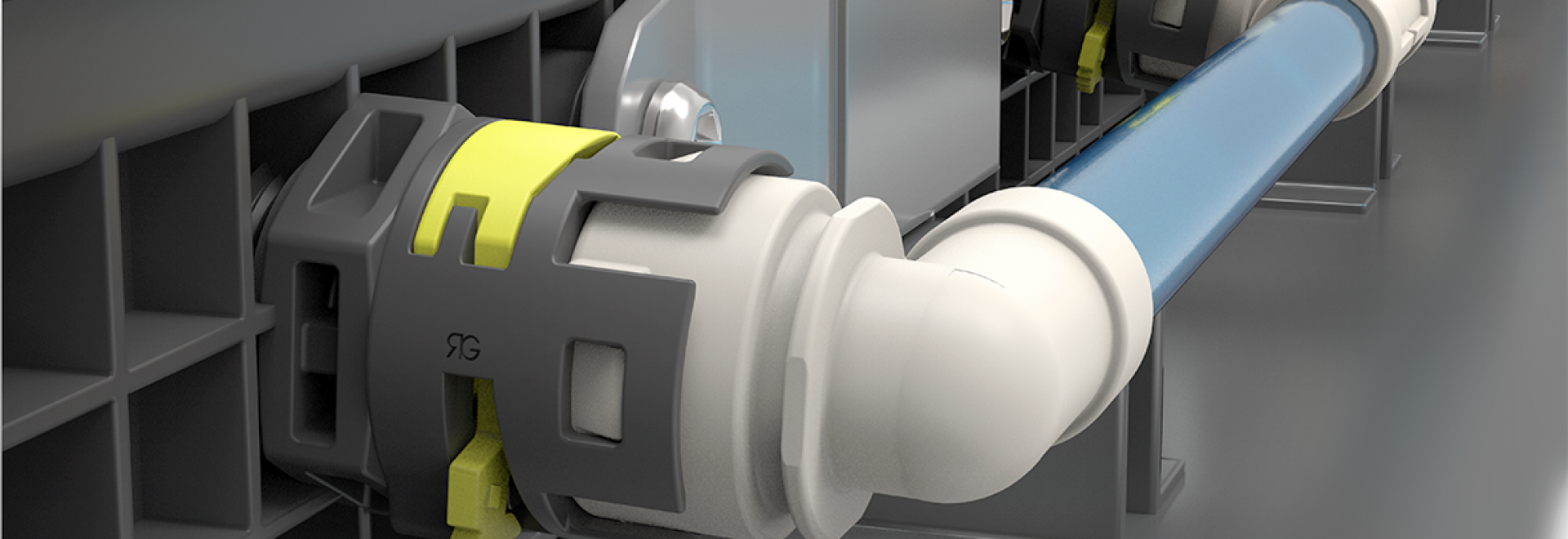

A key element of thermal management fluid interfaces is a reliable locking mechanism. ARaymond’s Selfy® Quick Connectors (QCs) provide visual, tactile, and audible assembly confirmation — so the installer both feels and hears the connection being made. Other options include the use of QR codes or DMC codes, allowing for better traceability. That data is available for review in the case of any issues developing with vehicles on the road, making it easier to identify possible root causes.

Ergonomic improvements

Another essential role played by improved connection systems for thermal management comes into play at the factory level, where they help improve conditions for the workers building EVs and installing EV fastening solutions. Installation points can be difficult to access, increasing the chance of a bad connection that could lead to reliability problems, as well as musculoskeletal issues for assembly plant workers accessing the installation point continually throughout the shift.

By making connectors, sealing interfaces and fasteners require less force to insert, these upgrades can improve the quality of life and health of workers while also improving vehicle safety. ARaymond’s VDA low-push QCs reduce insertion efforts by an average of 40% compared to industry standards, improving working conditions on vehicle assembly lines.

Considering the higher number of connectors needed on an EV it is especially beneficial. Larger connectors must be pushed in harder, so ergonomic improvements will make more difference for EV manufacturing, where fluid line connections are made manually.

By simplifying the architecture of fastener installation, OEMs are able to pass along a benefit to employees working on EVs that protects their health while also improving the vehicle.

Custom, versatile, and sustainable designs

Another important element to the improvements being made to thermal management fastening solutions is that each automaker has their own specific needs and specifications to serve their EV lineup, which leads to custom designs becoming an absolute necessity as OEMs work with suppliers to provide exactly what they need.

With a focus in the EV world on shaving off weight wherever possible to help with overall vehicle range, OEMs are using custom, compact, lightweight connection and sealing solutions in their EVs. The trend toward smaller connectors allows for better space optimization as well as weight reduction.

At ARaymond, custom products are offered in a range of shapes and sizes to fit each customer’s individual needs. Solutions such as ARaymond’s new Selfy® Compact QCs are specially designed to fit into tight spaces, maximizing coolant flow and allowing for high flexibility. ARaymond can also integrate temperature sensors and valves into our wide range of connectors to reduce fluid interfaces and optimize space.

Another important byproduct of these more compact and lightweight fasteners is the reduction of carbon emissions. Reaching our CSR goals and supporting our customers and suppliers to do the same, is a top priority at ARaymond. We’re constantly working on evolving the sustainability of our products and processes, through eco designs, lifecycle analyses, bio sourced or other alternative materials, among multiple other company wide measures.

At the end of the day, everyone involved in the EV transition wants to see safe vehicles reach the public and support positive working conditions for the people assembling these vehicles. While EVs are presenting new fastening challenges due to a focus on thermal management, ARaymond is rising to the challenge with products that improve vehicle safety, ergonomics at the assembly level, and custom solutions that will benefit the automakers as well as the environment.

By Sébastien Frasse-Sombet, Senior Global Product Manager, ARaymond